As regards strategy, whenever top management decide on their vision, the key question is how to organise the business as result, so that it genuinely creates value. The need to buy into this vision is increasingly important for employees, who are constantly looking for a point to their work, but day-to-day management and operational excellence to successfully implement the vision are needed just as much.

In the end, a vision without the ability to execute it is probably a hallucination.

co-founder of AOL

We have already talked about performance management methods, including the Hoshin Kanri method that is used to ensure that your strategy is properly understood and followed day-to-day. This method facilitates full involvement at all management levels, and the Nemoto diagram often serves to supplement it, by providing an interesting picture of roles and responsibilities within the organisation.

A definition of the Nemoto diagram

The diagram was devised by Masao Nemoto who is considered, along with Taiichi Ōno, as one of the iconic figures contributing most to the Toyota system’s performance. His inputs not only added much to the excellence of the quality management system, but also to the improvement in managerial practices and leadership principles in Toyota’s day-to-day operations.

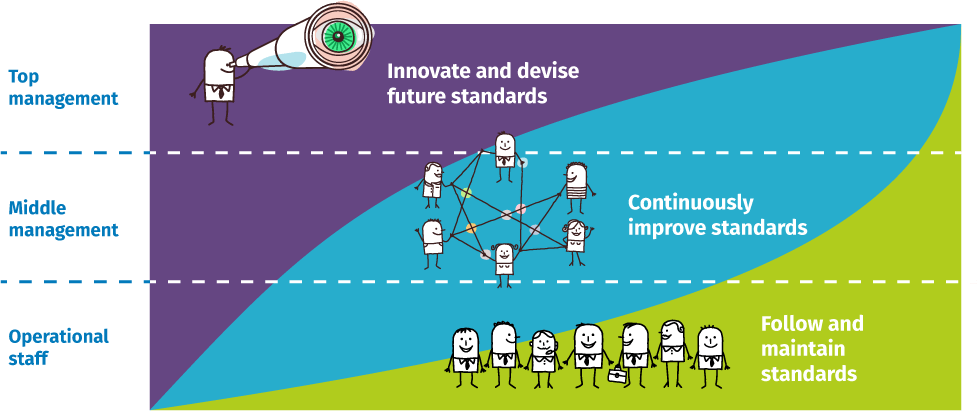

This was the backdrop to his creating the famous Nemoto diagram, to provide an instant crystal-clear picture of the roles and responsibilities of each individual according to the three main hierarchical levels found in any organisation:

- Senior management, which delivers its strategic vision and creates meaning for the workforce to unify employees around innovation and continuous improvement, thereby creating the dynamic that is crucial to any transformation.

- Middle management, which shares out objectives and determines standard processes. It then coordinates the activities of operational staff, striving to lift quality standards and improve working conditions by continuously analysing the reality at grassroots.

- Operational staff, who turn the vision into tangible products and services to create added value, by following the standards. Their level of commitment will also make it possible to escalate ideas and innovative suggestions to contribute to improving these standards.

While at first glance the diagram might give the impression that everyone is essentially kept in their place, this is not the case. To produce it, Masao Nemoto established key management and leadership principles. Top of the list are listening, coordination, mutual recognition and allowing everyone to speak freely. However, these principles also established that it is hugely important that everyone understands their role perfectly, and their contribution to value creation, so they can be fully engaged in the tasks delegated to them, and meet the targets and deadlines set. This is why the Nemoto diagram features prominently among Lean Management tools, to illustrate the strength of commitment from various organisational stakeholders in transforming and permanently improving business practices.

The galvanising effect of the Nemoto diagram and time management

Every manager plays a decisive role in operational excellence and the attainment of strategy objectives. To contribute to success, managers must instil meaning, and motivate their teams each and every day. A grassroots presence and contact with other people is therefore crucial but, unfortunately, often neglected for lack of time. And yet it is this very grassroots presence that enables managers to spot failures to adhere to standards, to keep the business vision in the minds of operational staff, to witness recognition for the work done, and to identify any skills development requirements. The question of the time that management allocate to various tasks and responsibilities, including their grassroots presence, arises every day, and the Nemoto diagram helps us answer it.

The diagram actually clearly shows that the proportion of time to be spent on different tasks varies across the three main hierarchical levels, but everyone has to spend some time on all of them. It is also obvious that the most important activity in the centre of the diagram is that of improving standards by middle management, which consequently connects the vision to the tangible implementation. However, this is far from always the case in businesses that need to rely more on their managers to push their maturity level in terms of operational excellence up more quickly.

Lastly, the Nemoto diagram also confirms that the business’ entire workforce has a role to play in the innovation and continuous improvement processes, thus contributing to the overall transformation of the organisation. An observation of this kind induces us to ask what governance and coordination mechanisms need to be implemented to galvanise this energy wisely and prevent initiatives becoming lost in the limbo of Excel or MS Project files. We consequently return to a key question that has already been raised: should a Competitiveness Department be created to coordinate all initiatives in line with the company's strategic objectives? A question that merits a degree of consideration, various aspects of which you can find in our article on Business Initiatives Lifecycle Management (BILM).

By way of further reading, take a look at how to manage your decision-making process in a more agile and more collective way depending on the complexity of the issue to be resolved, through the expert view of Olivier Zara, a trailblazer in the area of collective intelligence.